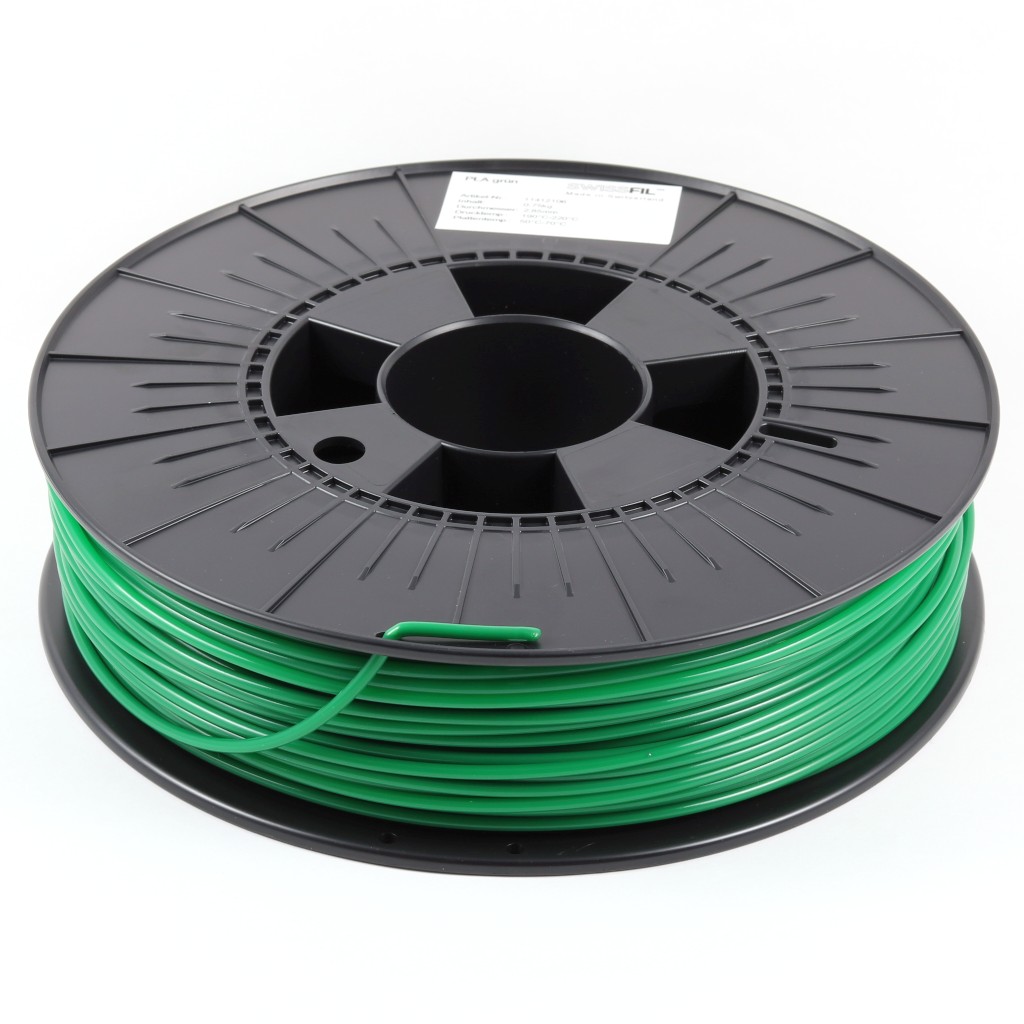

PLA

Poly Lactide Acid

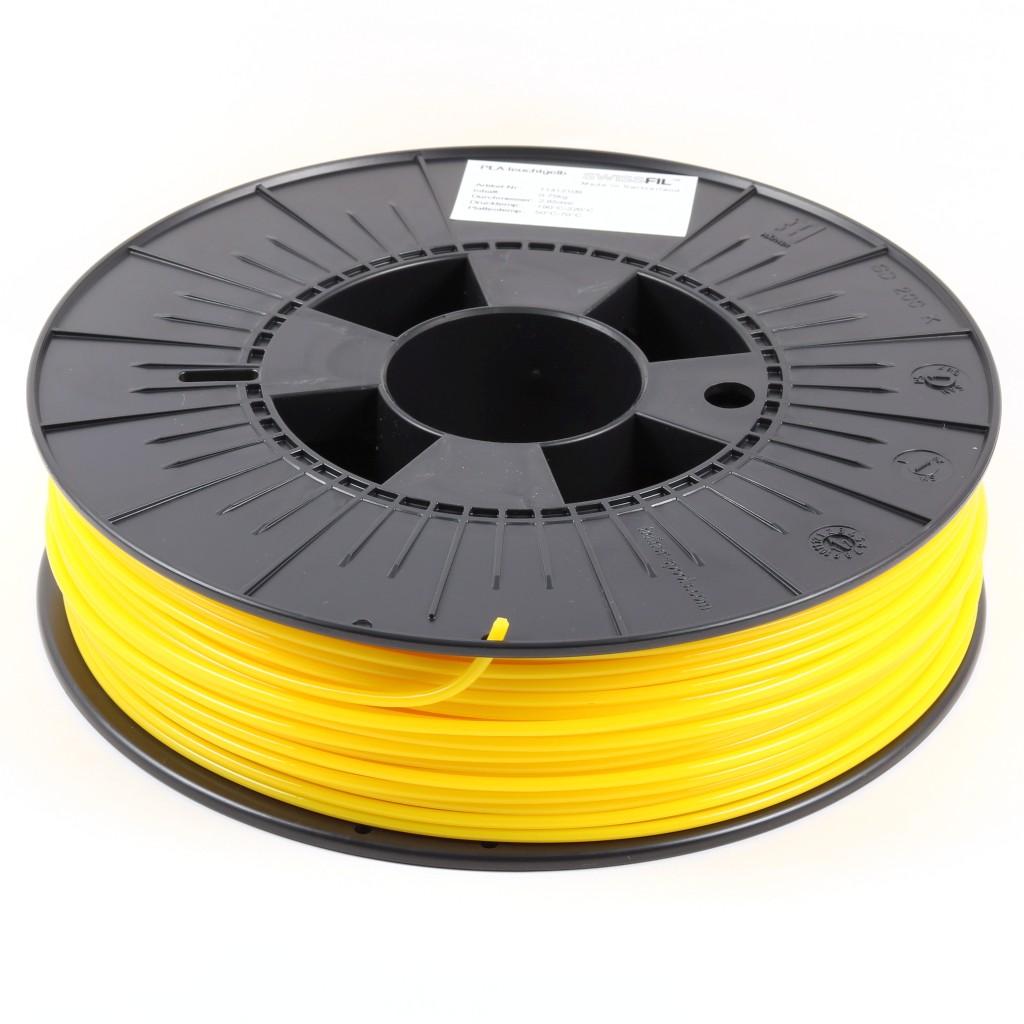

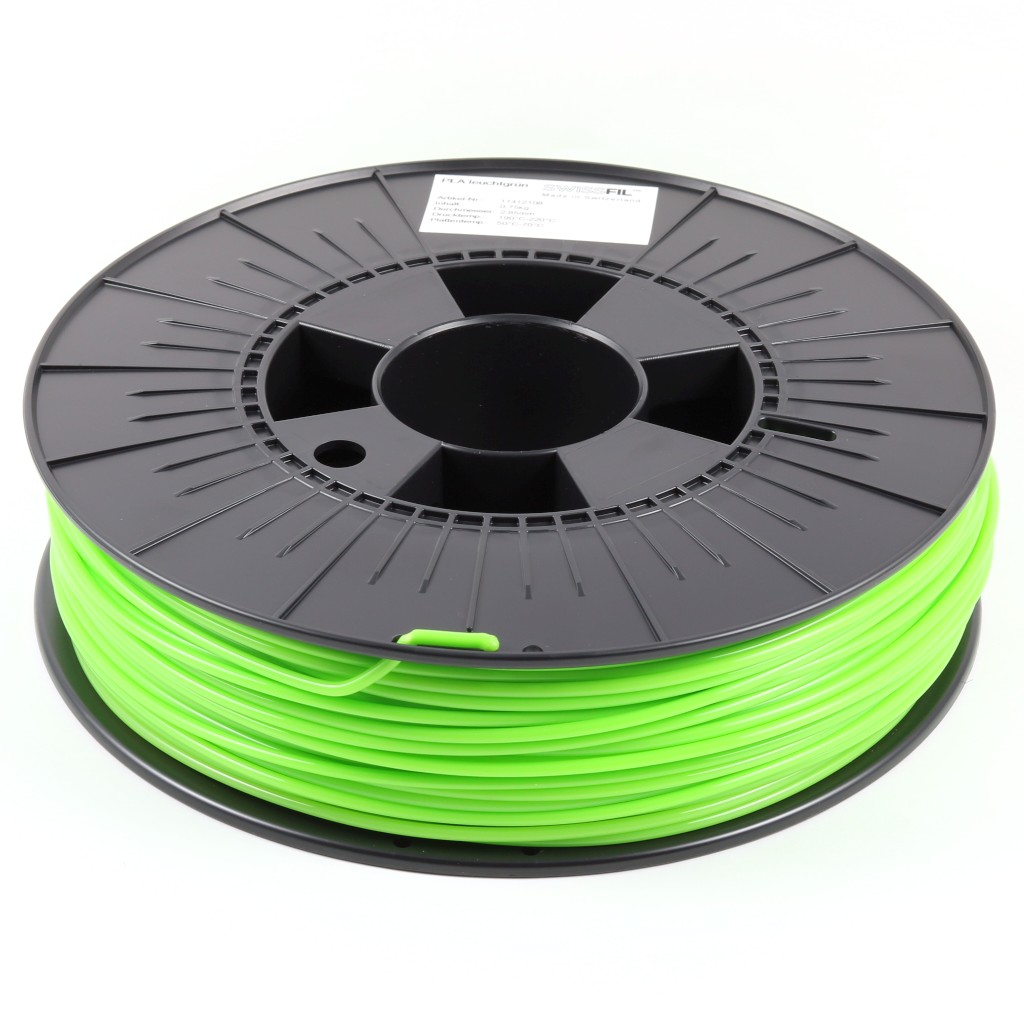

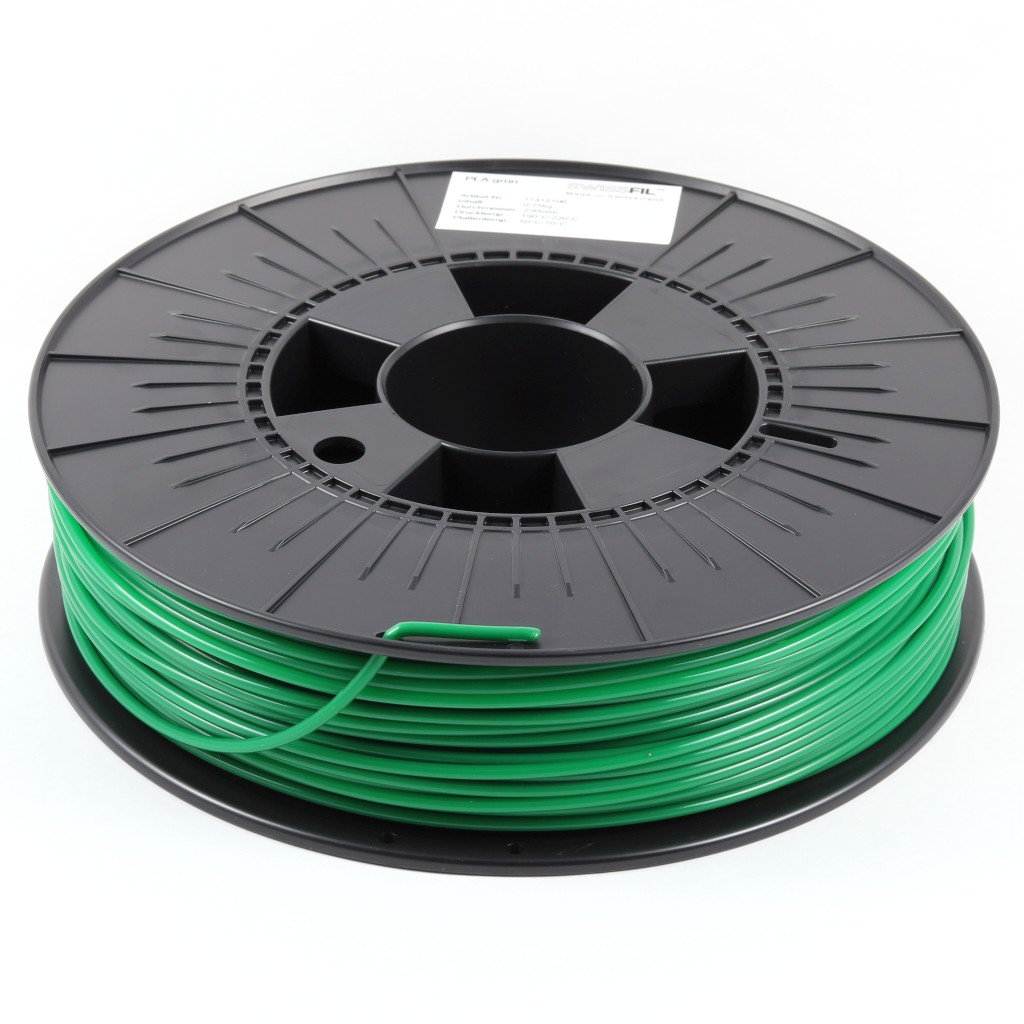

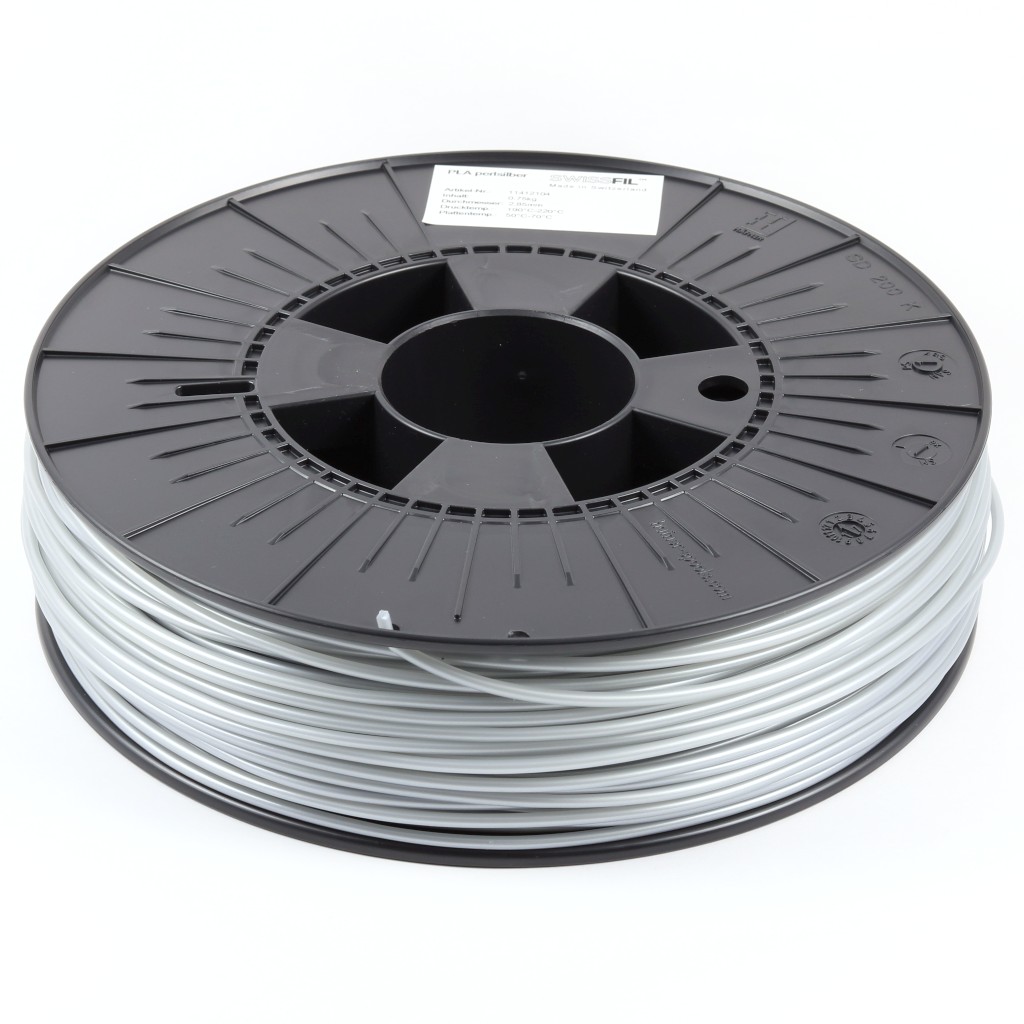

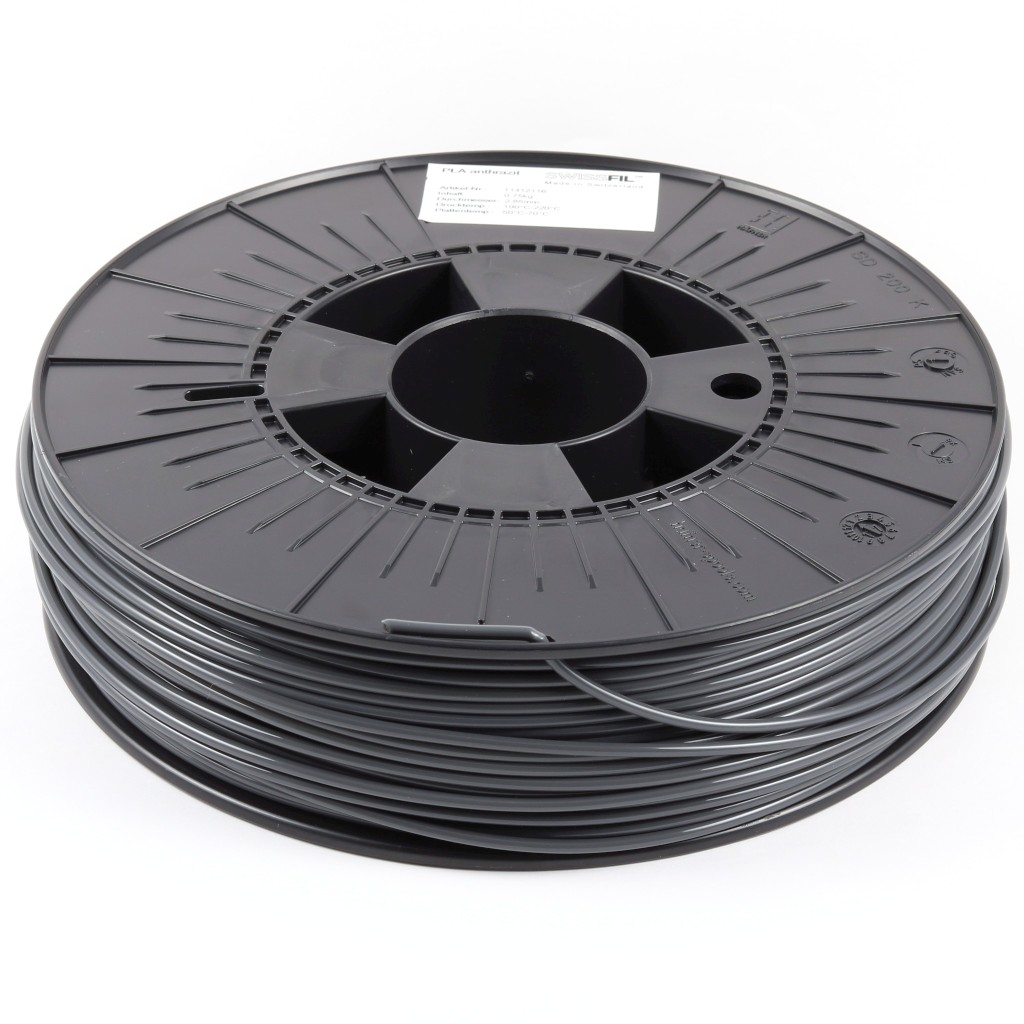

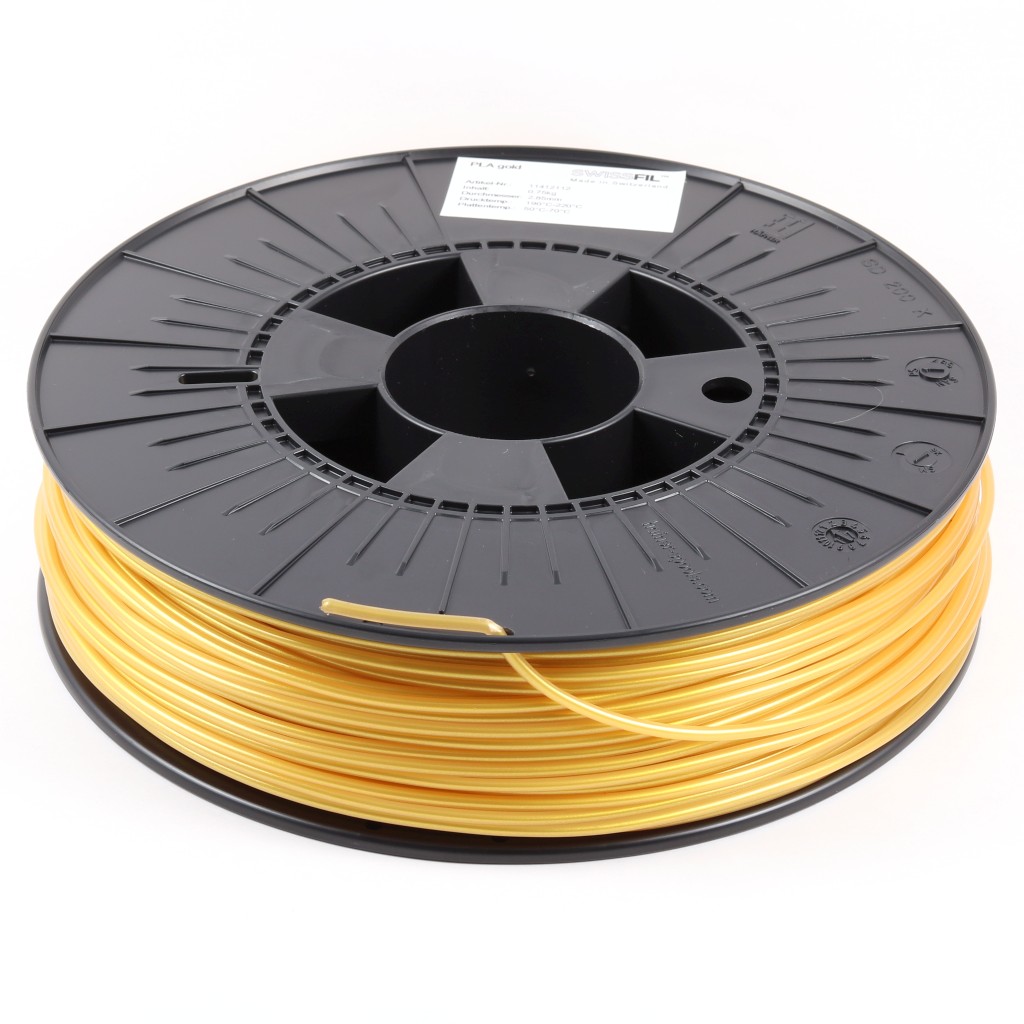

SWISSFIL® PLA 2.85mm is available in 19 different colors and transparent. SWISSFIL® PLA 1.75mm is currently available in black and white.

SWISSFIL® PLA also comes as the following specials:

|

Matt Black in 2.85mm |

|

Wood in 2.85mm and 1.75mm |

SWISSFIL® PLA has a heat deflection temperature around 55°C. It can be used for temperatures up to 45°C (continuous) and 60°C (short-period), respectively. The filament is bio-degradable, can be dissolved in many organic solvents and shows a high UV light resistance. It complies with flammability class V-2 of UL94. For further material properties please check the technical datasheet.

Typically, the PLA filament is printed at temperatures between 190-220°C. For better build plate adhesion a heated print bed is recommended with a build plate temperature of 50-70°C.

In case the PLA was stored in a humid enviroment for some time, drying is recommended before use. It can be dryed during two to four hours at 80°C.

Technical Datasheet |

Safety Datasheet |

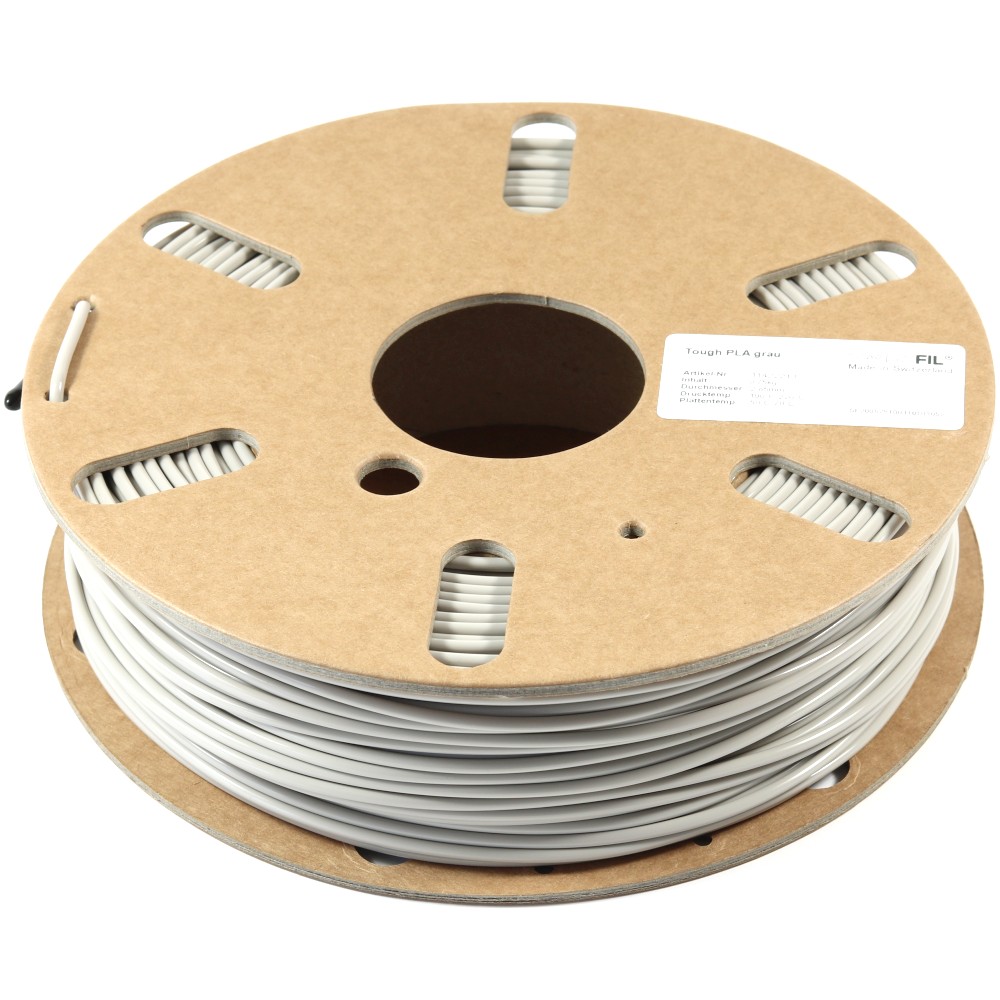

Tough PLA

Impact modified Poly Lactide Acid

Tough PLA is PLA made impact resistant by a special impact modifier.

SWISSFIL® Tough PLA 2.85mm gibt es in 3 verschiedenen Farben.

|

White in 2.85mm |

|

Black in 2.85mm |

|

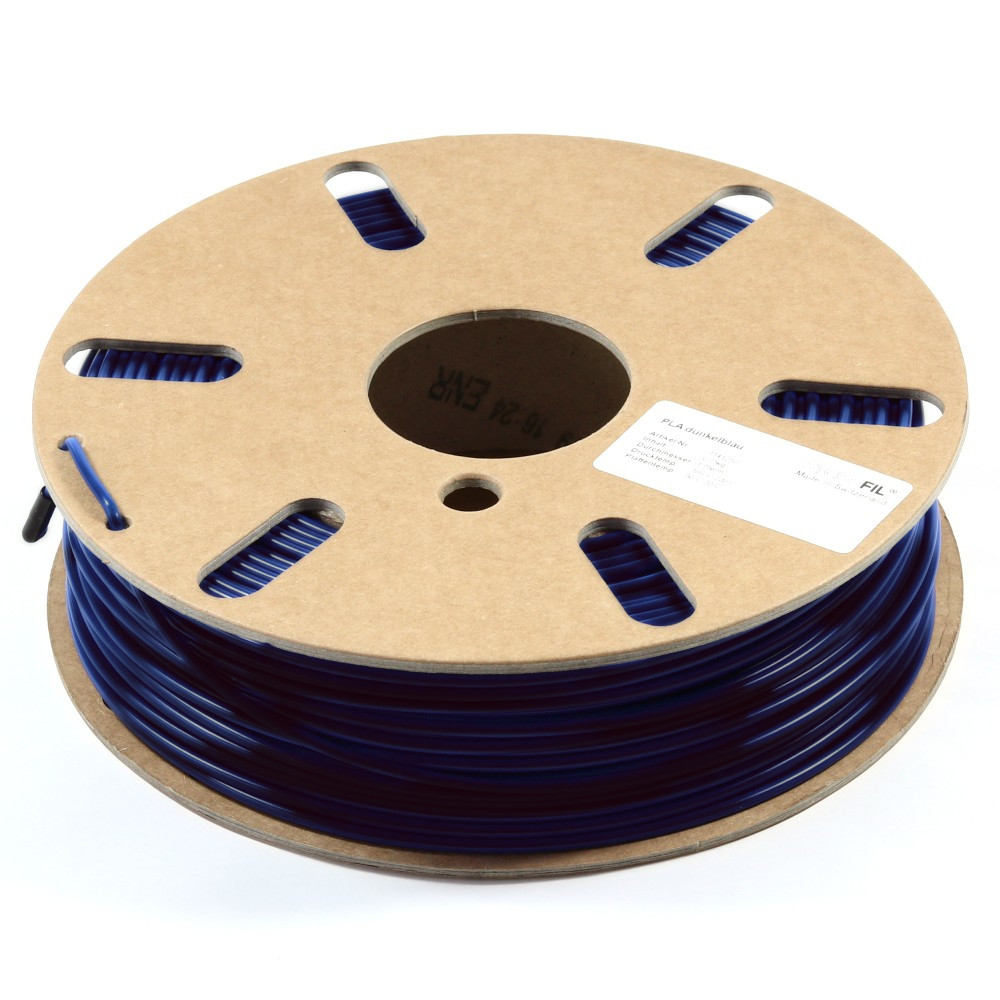

Dark Blue in 2.85mm |

|

Light Blue in 2.85mm |

|

Traffic Red in 2.85mm |

|

Orange in 2.85mm |

|

Yellow in 2.85mm |

|

Green in 2.85mm |

|

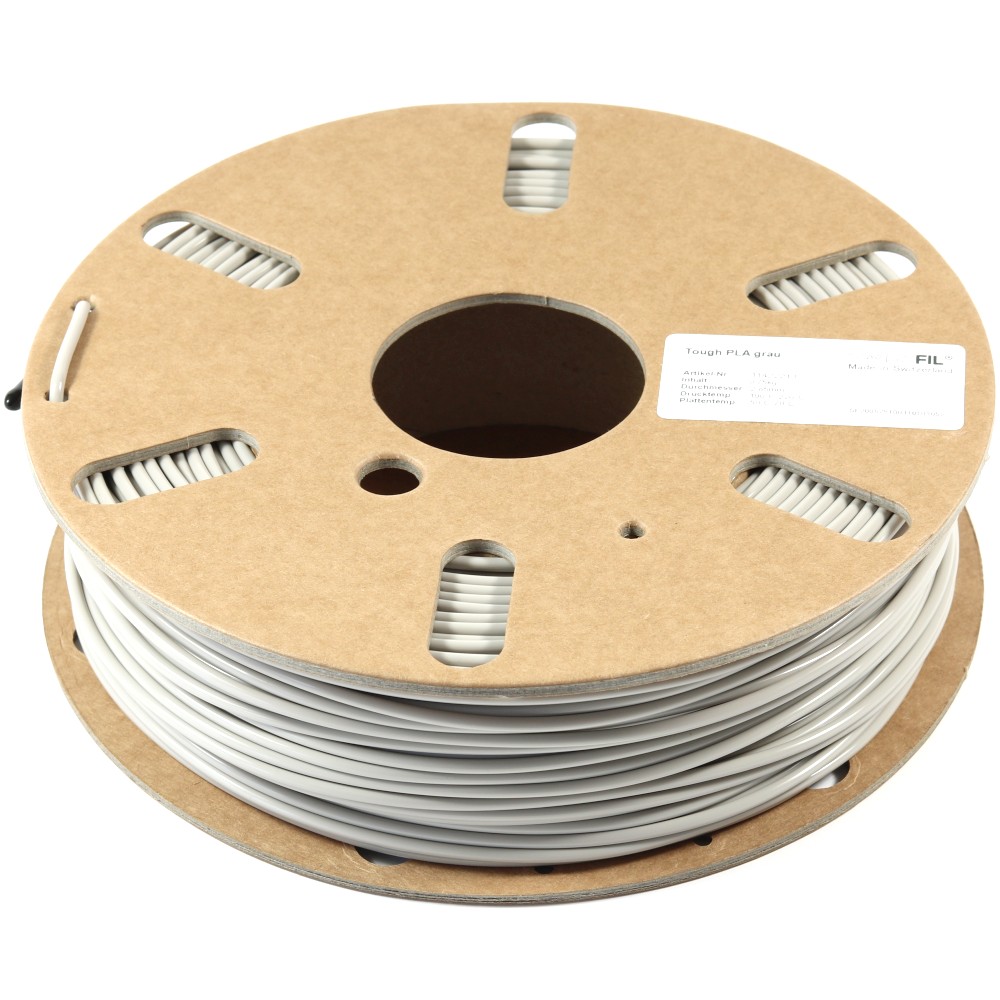

Grey in 2.85mm |

|

Anthracite Grey in 2.85mm |

SWISSFIL® PLA has a heat deflection temperature around 55°C. It can be used for temperatures up to 45°C (continuous) and 60°C (short-period), respectively. The filament is bio-degradable, can be dissolved in many organic solvents. It’s based on Ingeo™ PLA resin from Natureworks which is one of the purest and top grade PLA resins worldwide. Compared to standard PLA Tough PLA has an impact strength similar to ABS. For further material properties please check the technical datasheet.

Typically, the Tough PLA filament is printed at temperatures between 190-220°C. For better build plate adhesion a heated print bed is recommended with a build plate temperature of 50-70°C.

In case the Tough PLA was stored in a humid enviroment for some time, drying is recommended before use. It can be dryed during two to four hours at 80°C.

Technical Datasheet |

Safety Datasheet |

ASA

Acrylonitrile Styrene Acrylate

SWISSFIL® ASA 2.85mm is currently available in 11 different colors.

|

Black in 2.85mm and 1.75mm |

|

White in 2.85mm and 1.75mm |

|

Sky Blue in 2.85mm |

|

Green in 2.85mm |

|

Light Green in 2.85mm |

|

Yellow in 2.85mm |

|

Traffic Red in 2.85mm |

|

Brown in 2.85mm |

|

Concrete Grey in 2.85mm and 1.75mm |

|

Pearl Silver in 2.85mm |

|

Anthracite Grey in 2.85mm |

SWISSFIL® ASA has a heat deflection temperature around 92°C. It can be used for temperatures up to 80°C (continuous) and 95°C (short-period), respectively. The filament has an excellent UV-light and weather resistance and is therefore suitable for outdoor purposes. For further material properties please check the technical datasheet.

Typically, the ASA filament is printed at temperatures between 210-260°C. A heated print bed is needed with a build plate temperature of 80-100°C.

In case the ASA was stored in a humid enviroment for some time, drying is highly recommended before use. It can be dryed during two to four hours at 80°C.

Technical Datasheet |

Safety Datasheet |

PET-G

Polyethylene Terephthalate (with Glycol modification)

SWISSFIL® PET-G 2.85mm is currently available in 4 different colors including transparent.

|

Black in 2.85mm and 1.75mm |

|

White in 2.85mm and 1.75mm |

|

Transparent in 2.85mm and 1.75mm |

|

Concrete Grey in 2.85mm and 1.75mm |

SWISSFIL® PET-G is PET which is modified with glycol to make it printable. It can resist diluted acids, water at room temperature, various oils and greases and alcohols. It is weather-proof and has a high wear resistance, good electrical isolation properties and a strong creep resistance. For further material properties please check the technical datasheet.

Typically, the PET-G filament is printed at temperatures between 210-260°C. A heated print bed is recommended with a build plate temperature of 60-80°C.

In case the PET-G was stored in a humid enviroment for some time, drying is highly recommended before use. It can be dryed during two to four hours at 80°C.

Technical Datasheet |

Safety Datasheet |

![]()

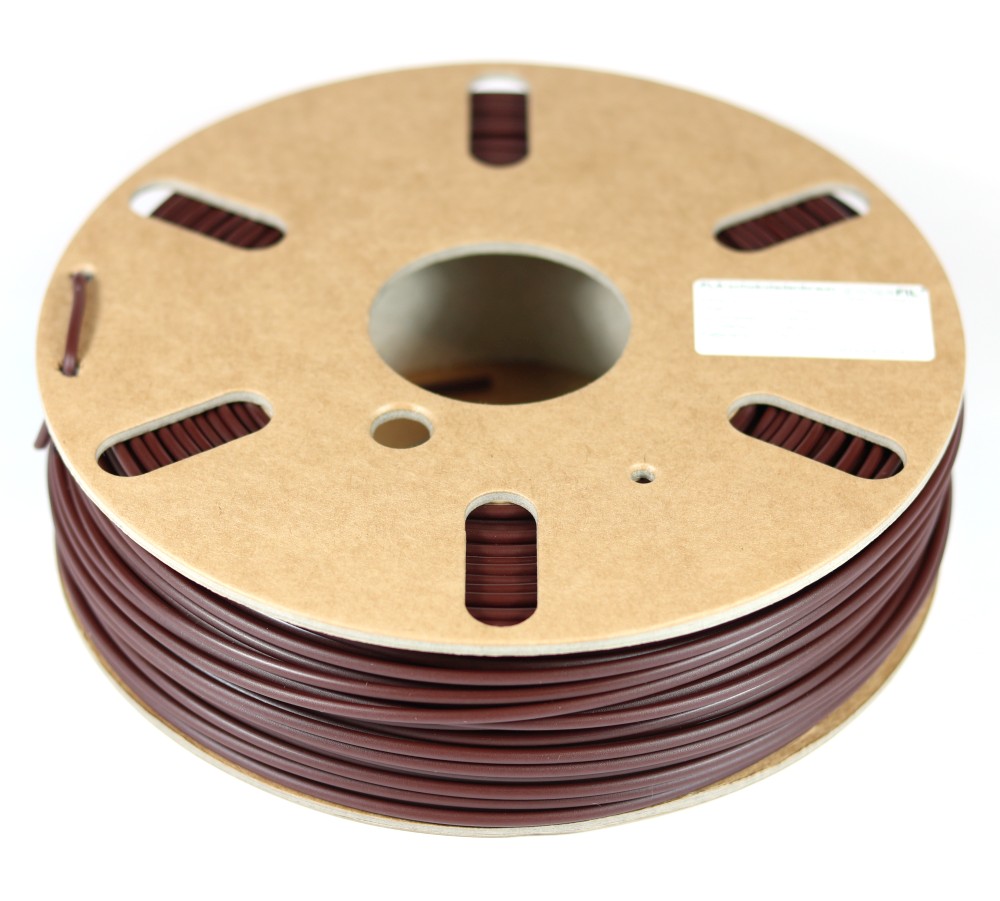

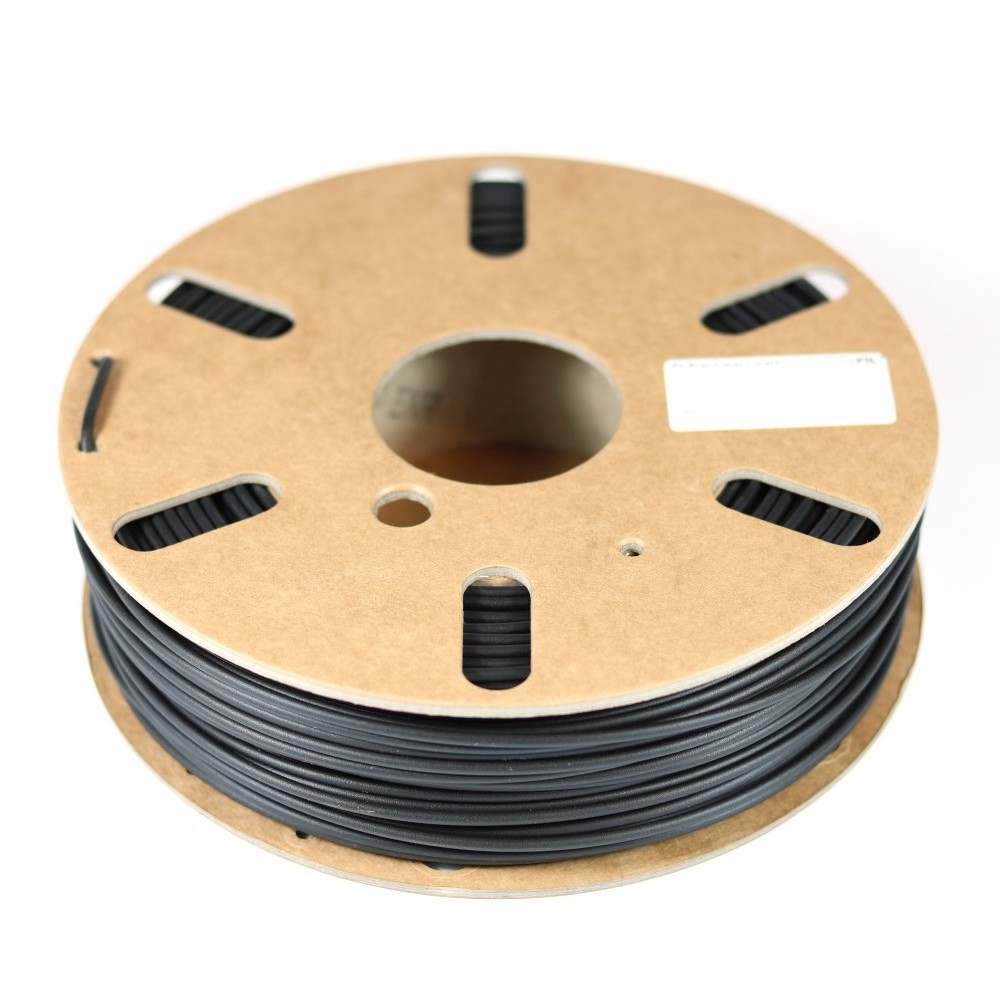

Since summer 2019 SWISSFIL® is shipped on cardboard spools. Thanks to a water-soluble glue, they can be fully recycled.

Since summer 2019 SWISSFIL® is shipped on cardboard spools. Thanks to a water-soluble glue, they can be fully recycled.